1 /

1

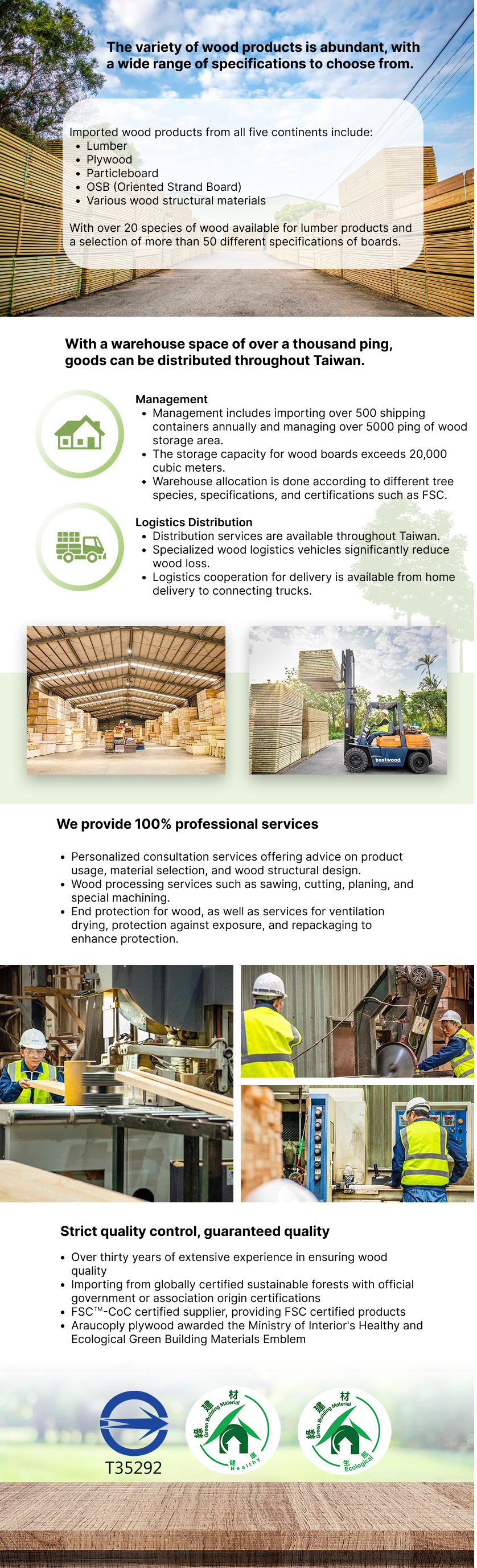

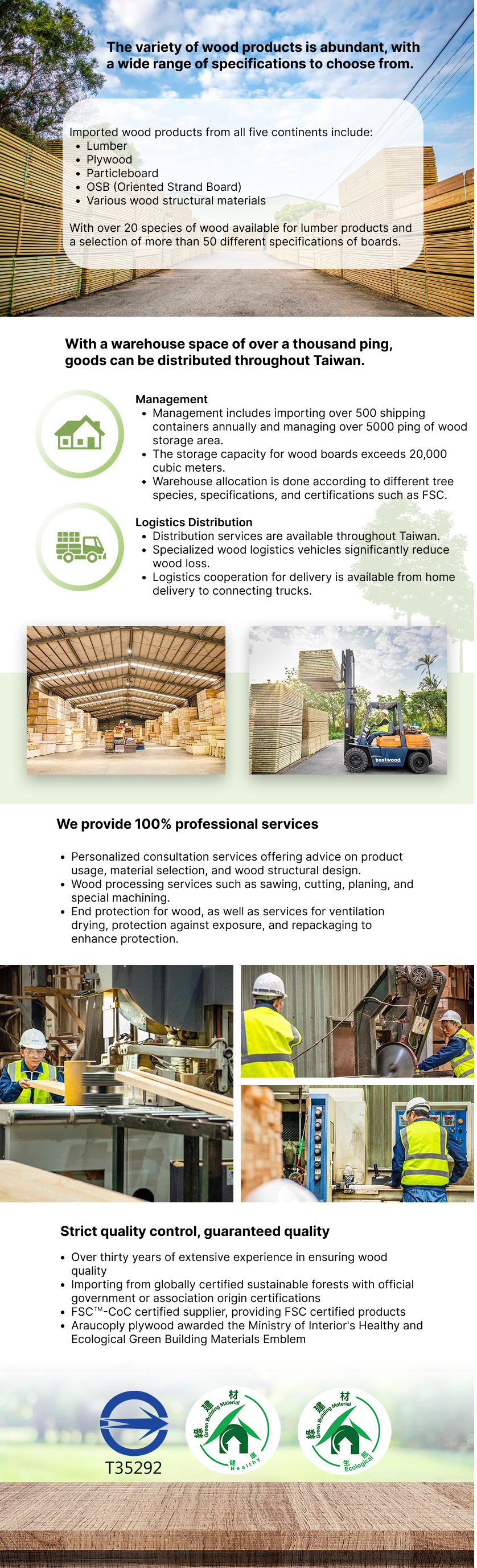

Birch Plywood

Description:

Thickness : 6 ~35 mm

Grade : Grade 1, Grade 1/2

Surface Film Style : Double-sided smooth

Color : Dark brown

-

European birch plywood, known as Finnish plywood, is a premium architectural plywood made with birch plywood as the base material and processed with surface film coating. The bottom layer of each panel is hot-pressed with layers of phenolic resin film for protection, increasing its durability against repeated concrete casting and outdoor exposure to sunlight and rain. It boasts excellent flatness, high reusability, and easy-to-clean surface after demoulding, effectively reducing the need for remodelling and associated costs.

The base material of Finnish plywood is birch plywood sourced from high-latitude regions in Europe. It is bonded with weather-resistant and boil-proof (WBP) phenolic resin adhesive, ensuring excellent load-bearing capacity and stability.

Phenolic Resin Coating

The surface of European birch plywood is coated with phenolic resin film, providing protection against wear and tear, moisture, and durability. Phenolic resin exhibits excellent heat resistance, water resistance, and insulation properties, making it highly suitable for concrete formwork applications. The use of phenolic film-coated plywood results in high abrasion resistance and moisture resistance, ensuring long-lasting performance.

Moisture Resistance and Weatherability

The bottom layer of Finnish plywood is covered with phenolic resin film, along with edge waterproof paint, reducing wear and tear during repeated concrete casting and enhancing its resistance to outdoor exposure to sunlight and rain.

High Reusability

When used as concrete formwork, the phenolic resin-coated surface facilitates easy cleaning and prevents sticking, effectively reducing the need for remodelling and associated costs. European manufacturers produce film-coated plywood according to technical specifications, allowing for over 50 times of reuse during concrete remodelling.

Certifications

Compliant with the U.S. Environmental Protection Agency (EPA) regulations on formaldehyde emissions from composite wood products

Compliant with the California Air Resources Board (CARB) standards for formaldehyde emissions from composite wood products

Compliant with Canadian regulations on formaldehyde emissions from composite wood products

Compliant with European standards for performance, qualification, and marking of engineered wood products for construction

Provides quantified information on the environmental impact at each stage of the product life cycle, allowing purchasers to choose environmentally sustainable products.Adventage of bestwood

-

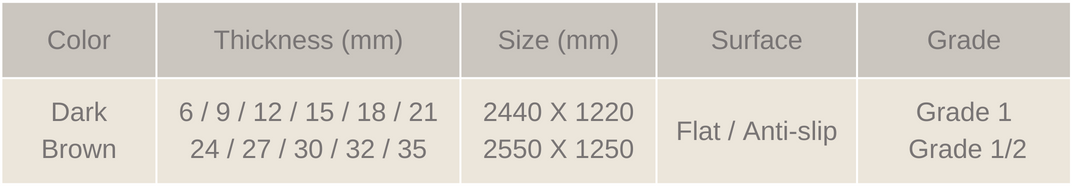

Film-Faced Birch Plywood Specifications

-

Finnish plywood is widely used in the construction and transportation industries. In construction applications, it is commonly employed as formwork for concrete casting. It is suitable for various construction projects, including horizontal formwork for high-rise buildings, shear walls, and vertical formwork, as well as for highway construction, elevated bridges, architectural fair-faced concrete, civil engineering tunnels, bridges, and retaining wall projects.

In the transportation industry, it is used as flooring material for trailers, trucks, ships, and containers. It finds applications in shipbuilding, cargo box manufacturing, various military and industrial products, as well as packaging.

-

Film-Faced Birch Plywood CharacteristicEuropean birch plywood, known as Finnish plywood, is a premium architectural plywood made with birch plywood as the base material and processed with surface film coating. The bottom layer of each panel is hot-pressed with layers of phenolic resin film for protection, increasing its durability against repeated concrete casting and outdoor exposure to sunlight and rain. It boasts excellent flatness, high reusability, and easy-to-clean surface after demoulding, effectively reducing the need for remodelling and associated costs.

The base material of Finnish plywood is birch plywood sourced from high-latitude regions in Europe. It is bonded with weather-resistant and boil-proof (WBP) phenolic resin adhesive, ensuring excellent load-bearing capacity and stability.

Phenolic Resin Coating

The surface of European birch plywood is coated with phenolic resin film, providing protection against wear and tear, moisture, and durability. Phenolic resin exhibits excellent heat resistance, water resistance, and insulation properties, making it highly suitable for concrete formwork applications. The use of phenolic film-coated plywood results in high abrasion resistance and moisture resistance, ensuring long-lasting performance.

Moisture Resistance and Weatherability

The bottom layer of Finnish plywood is covered with phenolic resin film, along with edge waterproof paint, reducing wear and tear during repeated concrete casting and enhancing its resistance to outdoor exposure to sunlight and rain.

High Reusability

When used as concrete formwork, the phenolic resin-coated surface facilitates easy cleaning and prevents sticking, effectively reducing the need for remodelling and associated costs. European manufacturers produce film-coated plywood according to technical specifications, allowing for over 50 times of reuse during concrete remodelling.

Certifications

Compliant with the U.S. Environmental Protection Agency (EPA) regulations on formaldehyde emissions from composite wood products

Compliant with the California Air Resources Board (CARB) standards for formaldehyde emissions from composite wood products

Compliant with Canadian regulations on formaldehyde emissions from composite wood products

Compliant with European standards for performance, qualification, and marking of engineered wood products for construction

Provides quantified information on the environmental impact at each stage of the product life cycle, allowing purchasers to choose environmentally sustainable products.Adventage of bestwood

-

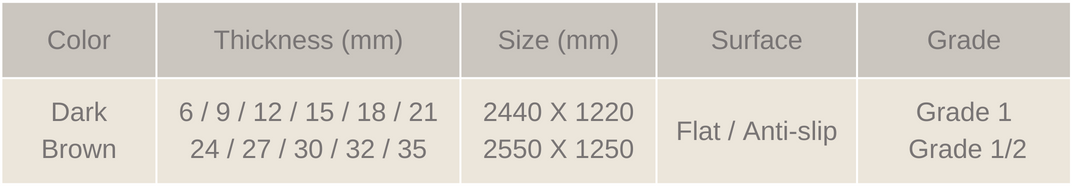

Film-Faced Birch Plywood SpecificationsFilm-Faced Birch Plywood Specifications

-

Film-Faced Birch Plywood ApplicationsFinnish plywood is widely used in the construction and transportation industries. In construction applications, it is commonly employed as formwork for concrete casting. It is suitable for various construction projects, including horizontal formwork for high-rise buildings, shear walls, and vertical formwork, as well as for highway construction, elevated bridges, architectural fair-faced concrete, civil engineering tunnels, bridges, and retaining wall projects.

In the transportation industry, it is used as flooring material for trailers, trucks, ships, and containers. It finds applications in shipbuilding, cargo box manufacturing, various military and industrial products, as well as packaging.