1 /

1

Slip-Resistant Birch plywood

Description:

Thickness : 6 ~ 35 mm

Surface Overlay Style : Smooth / Anti-slip

Color : Dark Brown / Black / Grey

-

Made from birch plywood as the base material, each sheet is coated with a layer of phenolic resin film, providing excellent slip resistance and durability, suitable for flooring applications in transportation vehicles and environments with strict conditions in construction. The unique embossed surface film enhances wear resistance and prolongs the lifespan of the flooring.

The resin-coated bottom layer ensures excellent weather resistance. The phenolic resin film on the bottom layer, along with the application of waterproof edge paint, enhances the flooring's resistance to chemicals and outdoor exposure to sunlight and rain when used in harsh environments.

Phenolic resin coating

Phenolic resin is known for its heat resistance, water resistance, and acid-alkali resistance. Flooring made with phenolic film coating boasts a smooth surface with a glossy finish, waterproofing, weather resistance, easy cleaning with water or steam, high wear resistance, and high reusability. It also withstands exposure to typical acidic and alkaline chemicals. When choosing plywood manufactured by European producers according to technical specifications, higher levels of durability and reusability can be achieved.

Anti-slip embossed surface

The birch anti-slip board features an embossed surface with an anti-slip pattern made of phenolic resin film. This enhances its anti-slip and wear-resistant properties. The attractive embossed pattern serves both decorative and functional purposes. Different film densities and surface patterns offer varying degrees of slip resistance, suitable for various applications requiring slip resistance and durability, such as recreational area flooring, stage flooring, or transportation container, carriage, and ship bottom flooring.

Certifications- Compliant with the Environmental Protection Agency (EPA) regulations on formaldehyde emissions from composite wood products.

- Compliant with the California Air Resources Board (CARB) standards for formaldehyde emissions from composite wood products.

- Compliant with Canadian regulations on formaldehyde emissions from composite wood products.

- Compliant with European standards for the performance, qualification, and labeling of engineered wood panels for construction.

- Provides quantified information on the environmental impact at each stage of the product life cycle, allowing purchasers to select environmentally sustainable products.

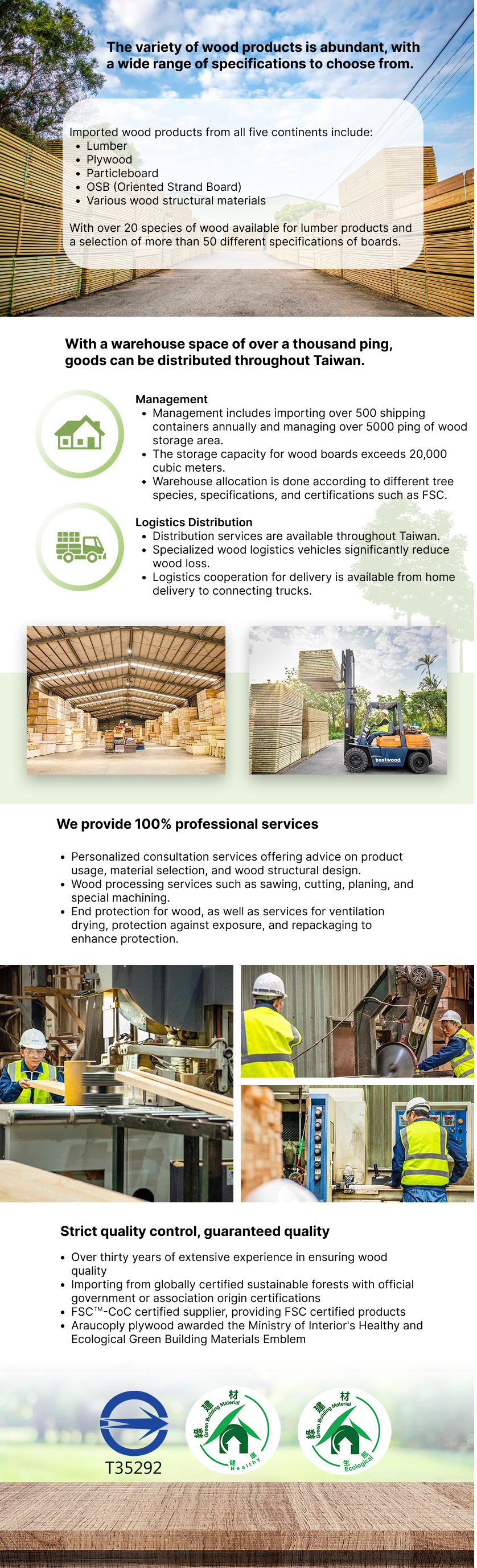

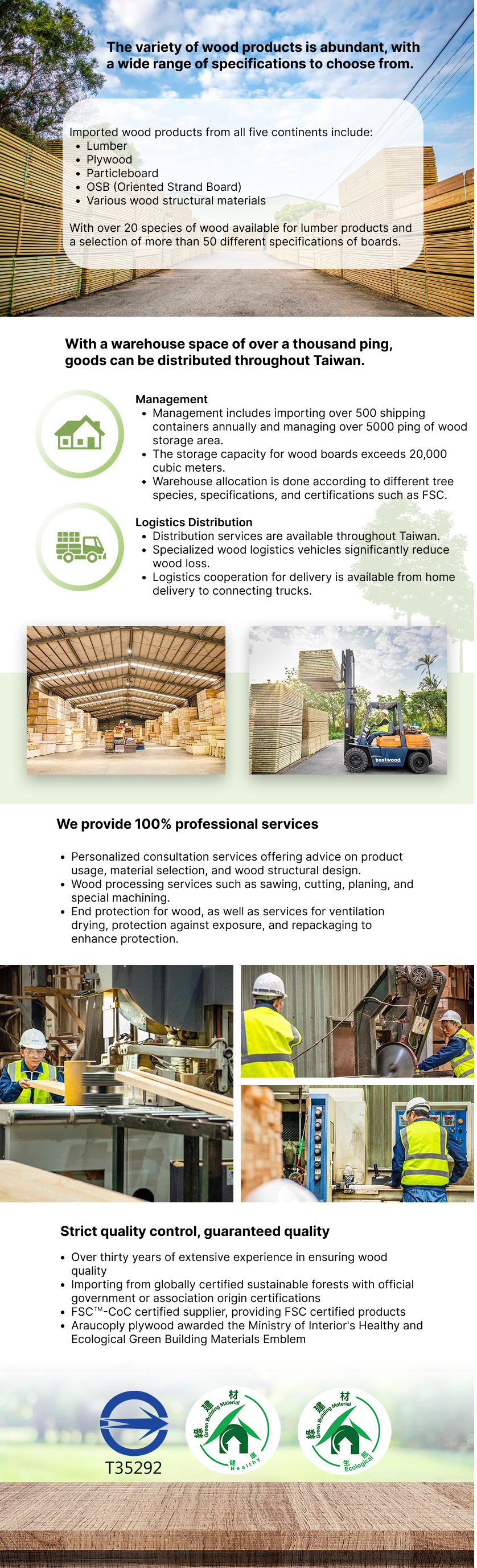

Adventage of bestwood

-

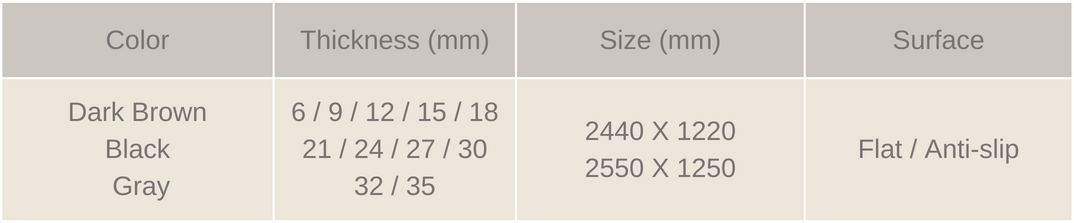

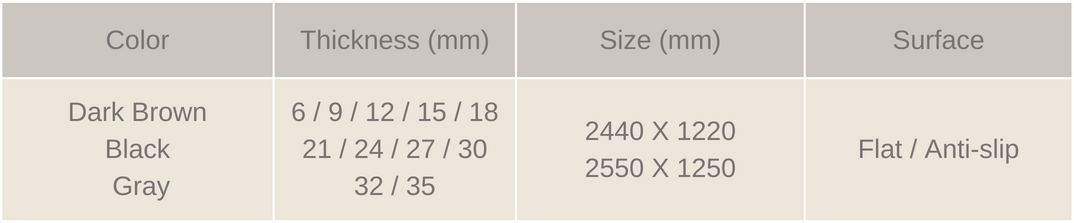

Slip-Resistant Birch plywood Specifications

-

European birch plywood, known for its excellent load-bearing capacity and high stability, is widely used in both the construction and transportation industries. In construction applications, slip-resistant birch plywood is commonly employed as formwork for pouring concrete. In the transportation sector, it serves as material for trailers, trucks, ships, and container flooring. Additionally, slip-resistant birch plywood finds applications in warehouses, loading docks, stages, playgrounds, sports fields, as well as decks and roof panels on ships. In building construction, slip-resistant birch plywood serves as formwork for pouring concrete or as exterior platforms.

-

Slip-Resistant Birch plywood CharacteristicMade from birch plywood as the base material, each sheet is coated with a layer of phenolic resin film, providing excellent slip resistance and durability, suitable for flooring applications in transportation vehicles and environments with strict conditions in construction. The unique embossed surface film enhances wear resistance and prolongs the lifespan of the flooring.

The resin-coated bottom layer ensures excellent weather resistance. The phenolic resin film on the bottom layer, along with the application of waterproof edge paint, enhances the flooring's resistance to chemicals and outdoor exposure to sunlight and rain when used in harsh environments.

Phenolic resin coating

Phenolic resin is known for its heat resistance, water resistance, and acid-alkali resistance. Flooring made with phenolic film coating boasts a smooth surface with a glossy finish, waterproofing, weather resistance, easy cleaning with water or steam, high wear resistance, and high reusability. It also withstands exposure to typical acidic and alkaline chemicals. When choosing plywood manufactured by European producers according to technical specifications, higher levels of durability and reusability can be achieved.

Anti-slip embossed surface

The birch anti-slip board features an embossed surface with an anti-slip pattern made of phenolic resin film. This enhances its anti-slip and wear-resistant properties. The attractive embossed pattern serves both decorative and functional purposes. Different film densities and surface patterns offer varying degrees of slip resistance, suitable for various applications requiring slip resistance and durability, such as recreational area flooring, stage flooring, or transportation container, carriage, and ship bottom flooring.

Certifications- Compliant with the Environmental Protection Agency (EPA) regulations on formaldehyde emissions from composite wood products.

- Compliant with the California Air Resources Board (CARB) standards for formaldehyde emissions from composite wood products.

- Compliant with Canadian regulations on formaldehyde emissions from composite wood products.

- Compliant with European standards for the performance, qualification, and labeling of engineered wood panels for construction.

- Provides quantified information on the environmental impact at each stage of the product life cycle, allowing purchasers to select environmentally sustainable products.

Adventage of bestwood

-

Slip-Resistant Birch plywood SpecificationsSlip-Resistant Birch plywood Specifications

-

Slip-Resistant Birch plywood ApplicationsEuropean birch plywood, known for its excellent load-bearing capacity and high stability, is widely used in both the construction and transportation industries. In construction applications, slip-resistant birch plywood is commonly employed as formwork for pouring concrete. In the transportation sector, it serves as material for trailers, trucks, ships, and container flooring. Additionally, slip-resistant birch plywood finds applications in warehouses, loading docks, stages, playgrounds, sports fields, as well as decks and roof panels on ships. In building construction, slip-resistant birch plywood serves as formwork for pouring concrete or as exterior platforms.